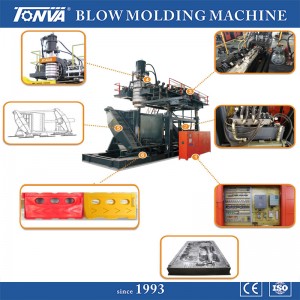

Palastik Jalan Blok Barricade Nyieun Mesin pe Tonjolan niup molding harga mesin

Panjelasan Produk

| Kategori | Barang | Unit | 1L | 2L | 3L | 5L | 12L | 20L | 30L |

| Spésifikasi Dasar | Bahan atah | — | PE / PP / PA / PVC jsb | PE / PP / PA / PVC jsb | |||||

| Diménsi | m | 2,7 x 1,6 x 1,9 | 3.1x2.0x2.0 | 3.2x2.0x2.0 | 3.5x2.1x2.1/3.7x3.0x2.1 | 4.3x3.5x2.2/4.6x4.4x2.2 | 5x5.9x2.35/5x6.5x2.4 | 53 x 6,4 x 2,4 | |

| Total Beurat | T | 2.3Z4.2 | 3.2Z6.5 | 3.4Z6.8 | 4.878.5 | 12/13 | 17/18.5 | 20 | |

| Sistim ékstrusi | Motor sekrup | KW | 7.575.5 | 15/7.5 | 18.5/15 | 22/18.5 | 30(37)/22 | 55/37 | 75/55 |

| Diaméter screw | mm | 55/45 | 65/55 | 70/65 | 80/70 | 90/80 | 100/90 | 110/100 | |

| Screw L / rasio D | L/D | 23:1/23:1 | 25:1/23:1 | 23:1/25:1 | 23:1/23:1 | 25:1 (28:1)/23:1 | 28:1/28:1 | 28:1/28:1 | |

| kakuatan pemanasan Extruder | KW | 7 | 15 | 18 | 20 | 23 | 28 | 30 | |

| Jumlah zona pemanasan | PCS | 3 | 3 | 3 | 4 | 5 | 7 | 8 | |

| Kapasitas plasticizing | kg/h | 55 | 70 | 75 | 95 | 120/130 | 160 | 180 | |

| Kepala maot | Zona pemanasan | PCS | 3-5 | 3-7 | 3-7 | 3-9 | 3-12 | 3-11 | 3-5 |

| kakuatan pemanasan | KW | 1.5-3 | 2-4.5 | 2.5-5 | 3-6 | 5-9.5 | 8-14 | 10-12 | |

| Jumlah rongga | — | 1-4 | 1-6 | 1-6 | 1-7 | 1-10 | 1-5 | 1-2 | |

| Sistim clamping | Jarak ngageser | mm | 300 | 360/400 | 360/400/450 | 450/550 | 600/650/700/800/850 | 700/800/850 | 800/900 |

| Jarak clamping | mm | 150 | 200 | 200 | 250/200 | 350/250/200 | 350/250 | 400/350 | |

| Buka stroke | mm | 160-310 | 160-360 | 180-380 / 160-360 | 230-480 / 180-380 / 160-360 | 330-680 / 250-500 / 240-440 | 380-730 / 330-680 / 300-550 | 420-820 / 380-730 | |

| kakuatan clamping | kn | 50 | 80 | 90 | 100 | 125/180 | 180 | 200 | |

| Konsumsi kakuatan | Total kakuatan | KW | 14-16/23-25 | 24-26/42-45 | 37-41 / 48-52 | 44^16/59-63 | 72-78 | 80-110 | 136-140 |

| Tekanan hawa | MPa | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | |

| Konsumsi hawa | m3/ mnt | 0.6/0.4 | 0.8/0.4 | 0.8/0.6 | 1 / 0.8 | 0.8 | 1 | 1.1 | |

| Konsumsi cai | m3/ h | 0.6/1 | 1/1.2 | 1/1.2 | 1.2/1.5 | 1.5 | 2 | 2.2 | |

Bengkel Pabrik

Jasa Kami

Bales pamundut sareng nyandak tindakan dina 24 jam.

Niupan kapang jeung suntik kapang dijieun di TONVA parusahaan aslina.

100% pamariksaan Kualitas sateuacan kiriman.

mesin bantu pikeun garis lengkep.

Nyadiakeun jasa latihan di parusahaan TONVA atawa pabrik clinet urang.

Desain ngaropéa sadia sakumaha sarat.

Insinyur pikeun pamasangan luar negeri sayogi

Nyadiakeun jasa konsultasi dina pamundut.

Ruang Sampel

Custormers

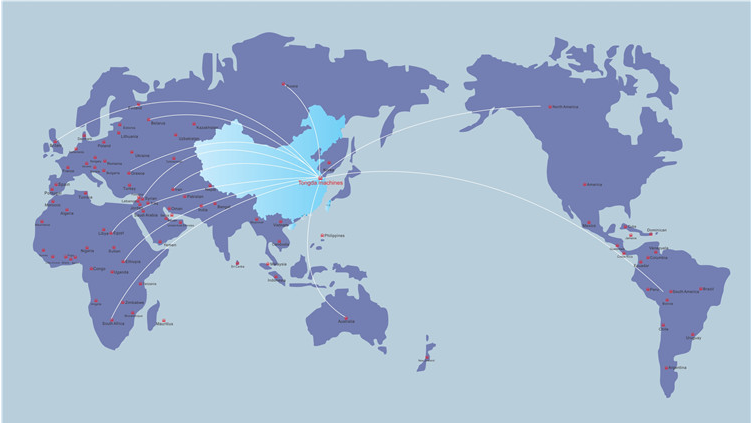

Jaringan Pemasaran Jasa

mesin kami geus ngalayanan konsumén sakuliah dunya.

Bungkusan & Logistik

Panjelasan Produk

Tulis pesen anjeun di dieu sareng kirimkeun ka kami